In the world of horology, time seems to run much more slowly. Compared to other industries, ground-breaking innovations in the realm of watchmaking tend to come about at a much slower rate. Consider the mobile phone for example. The first commercially viable mobile phone appeared in 1983, and just over two decades later, we were presented with the iPhone which set the standard for a modern smartphone. In comparison, advances in mechanical watches take far longer to develop. The reason for this is that the acquisition of knowledge and experience to design and improve on high-end mechanical timepieces is a time-consuming task, owing to the complexity of their designs which utilise a multitude of tiny components which must be fitted with granular precision.

When comparing the modern and vintage mechanisms which powered watches now and in the past, one would find that their basic designs are rather similar in form and function. There is however, a key difference between the designs from these two periods is the size of the timepiece’s movements and complications. Since we started strapping watches to our wrists in the Boer war, watchmakers have been obsessed with making them smaller and more wearable while retaining functionality. A great example of this is the evolution of watches with a perpetual calendar complication. For the uninitiated, the perpetual calendar is a grand complication which displays the date without the need for manual adjustments, much like the calendar built into a smartphone or digital watch.

Perpetual calendars have long been considered to be one of the most complicated complications, pun intended. With the number of components that make up this complication, it’s little wonder that watches with a perpetual calendar are typically thicker in size. Therefore, innovations in this field have mostly revolved around slimming down the profile of these watches. Earlier this year, Bvlgari succeeded in setting a new record for the slimmest perpetual calendar with its Octo Finissimo. The automatic calibre BVL 305 measures just 2.75mm and is made up of a jaw-dropping 408 components, all housed in a lean 5.8mm thick titanium case.

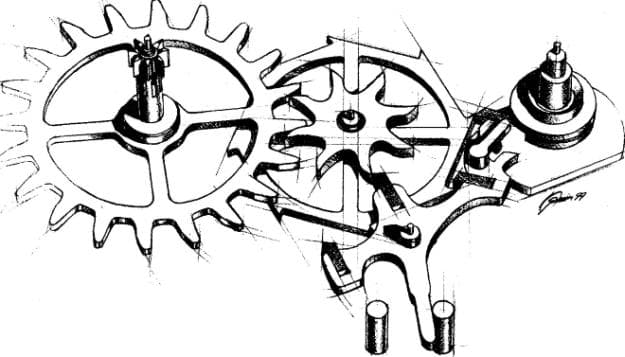

With components that are so tiny, people often forget that the cams, levers and gears which make up a timepiece’s movement are still subject to the same issues of wear and tear as any mechanical instruments. Over time, these could affect the timepiece’s ability to tell time accurately and reliably. In a bid to overcome this issue and prolong the lives of timepieces, a watchmaker by the name of George Daniels worked the problem tirelessly and invented the Co-Axial escapement. It was the first major advancement in watch design in over 200 years and worked by distributing an escapement’s moment to moment friction across three pallets, making it more durable and accurate over time that the traditional Swiss lever escapement.

Upon inventing the Co-Axial escapement, Daniels beginning pitching his idea to watch manufactures. However, most weren’t convinced of its effectiveness. Omega was the only brand he managed to win over and in 1999, the first Omega-branded Co-Axial escapement was released, being a feature of their de Ville Co-Axial limited edition timepiece. Since then, countless models have been built specifically to optimise the functionality of the Co-Axial escapement.

As advances in the field of material science grew, so too did the knowledge of watchmakers who were busy experimenting and adding new materials to their repertoire. One of the most significant advancements in watchmaking is the use of silicon. Most of a watch’s movement is made up of various metals which, when subjected to the elements or magnetic fields, could affect a watch’s overall performance and reliability. The simple solution to such a problem would be to of course find a non-ferrous material to replace these metal components. However, the chosen material would have to possess the same degree of mechanical strength and durability metals are known for. Ulysse Nardin’s answer was the use of silicon, also called silicium in the industry. Compared to traditional materials, silicon offers an enhanced stability at various temperatures, greater transfer of energy, and corrosion resistance among other things. The watchmakers at Ulysse Nardin applied their extensive knowledge, attained over years of experimentation, and developed several models with silicon components. Most notable among them are the Freak Vision, released in 2001, and the InnoVision in 2007, which featured an over-the-top use of silicon, showcasing the material’s potential in the construction of watches.

There are definitely many other significant innovations in the watch industry, but it would be impossible to cover them all in a single article. Suffice to say that all these developments are a tribute to the skills and vast knowledge of master watchmakers, many of whom have dedicated their whole lives to continuous learning and improvement. Without the experience housed within their noggins, we wouldn’t be able to admire and enjoy the complex art that is luxury watchmaking.

The post A Watchmaker’s Knowledge and its Links to Horological Innovations appeared first on LUXUO.

from LUXUO

No comments:

Post a Comment